Optimizing Your Supply Chain: How to Efficiently Pack and Ship

In today’s fast-paced logistics environment, the ability to efficiently pack and ship goods is crucial for maintaining a smooth and effective supply chain. Whether you’re a warehouse supervisor or an operations manager overseeing daily inbound and outbound activities, mastering the integration of packing and shipping processes can significantly enhance your operation’s efficiency. At Milky Way Logistics, we understand the importance of streamlining these processes to optimize performance and reduce costs.

In this blog, we’ll explore key considerations for integrating your pack and ship operations, ensuring that your warehouse runs like a well-oiled machine.

The Importance of a Well-Designed Pack and Ship Setup

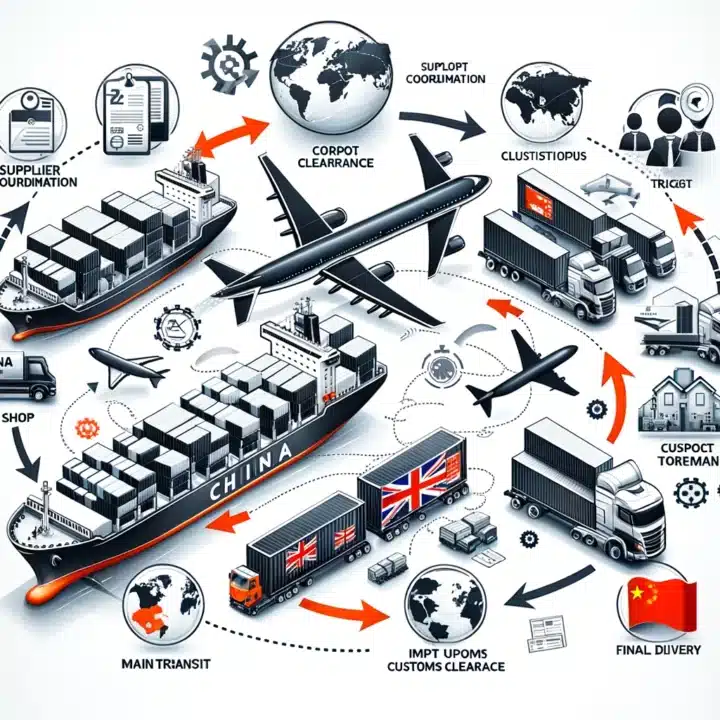

The integration of packing and shipping is more than just a logistical necessity—it’s a strategic advantage. When these processes are not seamlessly connected, it can lead to inefficiencies that disrupt the entire supply chain. For instance, packers may waste valuable time by manually moving consignments to specific shipping areas, or by dealing with disjointed systems that don’t communicate effectively. These inefficiencies not only slow down operations but can also increase costs and reduce overall productivity.

To combat these challenges, it’s essential to design a setup that allows for smooth coordination between packing and shipping tasks. By implementing an integrated system, you can ensure that your pack and ship processes are aligned, reducing the likelihood of delays and errors. This integration can significantly enhance your workflow, enabling you to move products from the packing stage to the shipping stage quickly and efficiently.

Streamlining Workflow: The Smart Way to Pack and Ship

One of the most effective ways to optimize your packing and shipping operations is to streamline your workflow. This means creating a system where packing and shipping processes are not only integrated but also designed to work in harmony. For example, instead of running separate applications for packing and shipping in different areas of the warehouse, consider using a unified system that allows both operations to be managed from a single platform.

This approach not only saves time but also reduces the complexity of training staff on multiple systems. With a unified system, your team can learn one process that covers both packing and shipping, making the overall operation more efficient. Additionally, this setup allows for better monitoring and management of the entire supply chain process, ensuring that any issues can be quickly identified and resolved.

Enhancing Efficiency with the Right Tools and Systems

To truly optimize your pack and ship operations, it’s essential to have the right tools and systems in place. This includes everything from software solutions that integrate packing and shipping processes to physical infrastructure that supports efficient workflow. For example, automated packing systems can help speed up the packing process, while conveyor belts and sorting systems can streamline the movement of goods to the shipping area.

Moreover, investing in technology that allows for real-time tracking and monitoring of shipments can further enhance your operation’s efficiency. With real-time data, you can make informed decisions that improve the speed and accuracy of your pack and ship processes. This not only boosts performance but also helps to reduce the overall cost of operations.

Training and Implementation: Key to Successful Pack and Ship Integration

While having the right systems in place is crucial, it’s equally important to ensure that your team is well-trained and capable of utilizing these systems effectively. Implementing an integrated pack and ship system requires careful planning and execution, with a focus on training employees to handle the new processes. This includes teaching them how to use the new systems, as well as understanding the importance of each step in the pack and ship process.

At Milky Way Logistics, we emphasize the importance of comprehensive training programs that equip our team with the skills needed to operate efficiently in a dynamic logistics environment. By investing in training, we ensure that our staff can handle the demands of integrated pack and ship operations, leading to improved performance and customer satisfaction.

The Benefits of a Well-Integrated Pack and Ship System

When your pack and ship processes are fully integrated and optimized, the benefits are clear. You’ll see increased efficiency in your operations, with faster turnaround times and reduced costs. The streamlined workflow will lead to fewer errors, which in turn will enhance the reliability of your supply chain. Moreover, by reducing the time spent on packing and shipping, you’ll free up resources that can be redirected to other critical areas of your business.

Additionally, a well-integrated pack and ship system can improve customer satisfaction by ensuring that orders are processed and delivered quickly and accurately. In today’s competitive market, this level of service can set your business apart from the competition.

Conclusion

The ability to efficiently pack and ship is a critical component of a successful supply chain. By integrating these processes and optimizing your workflow, you can achieve significant improvements in efficiency, cost savings, and customer satisfaction. At Milky Way Logistics, we are committed to helping our clients navigate the complexities of packing and shipping, ensuring that their operations run smoothly and effectively.

If you’re looking to enhance your pack and ship operations, consider the benefits of a well-integrated system. With the right setup, tools, and training, you can streamline your processes and achieve the operational excellence that today’s logistics landscape demands.

No comments

… [Trackback]

[…] Find More on that Topic: mwll.co.uk/how-to-pack-and-ship-at-the-same-time/ […]

… [Trackback]

[…] Find More Information here to that Topic: mwll.co.uk/how-to-pack-and-ship-at-the-same-time/ […]